Wheels & TIres 101

Page 1 of 1

Wheels & TIres 101

Wheels & TIres 101

TECHNICAL INFORMATION ABOUT WHEELS AND TYRES

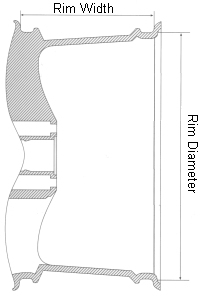

WHEEL MEASUREMENTS

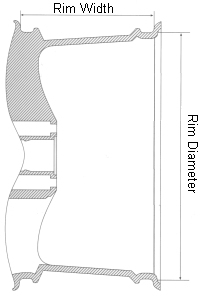

A standard measurement for a wheel is given using several figures, e.g. 18 x 8, 4 x 108, 35

This can be broken down as follows:18 x 8 represents a wheel which is 8 inches wide and 18 inches in diameter.

4 x 108 represents the number of studs/bolts and the PCD in millimeters (explained later).

35 represents the Offset (sometimes referred to as the ET).

PITCH CIRCLE DIAMETER (PCD)

The number of bolts used to install a wheel varies from 3 to 8 studs depending on the vehicle make and model. The pitch is the diameter (mm) of the circle that intersects the stud centres. To fix a wheel correctly, the number of studs and the pitch should be the same on the vehicle and the wheel.

The following calculations can be used to work out the PCD:

6-stud - Length 'X' x 2

5-stud - Length 'X' x 1.7012

3-stud - Length 'X' x 1.154

4-stud - Measure the length between the centers of opposite Studs.

In the Trade we use a Measuing Tool for this.

This Tool is calibrated with the Formula's above, so that you simply measure stud to stud, This one will also give American Spec Sizes.

Common Stud Patterns:

3 x 98

4 x 95.25 Mini / MGF

4 x 98 Fiat

4 x 100 Reanult / Vauxhall / Opel / VW

4 x 108 Ford / Peugeot / Citroen

4 x 114.3 Mostly Jap Suzuki / Honda

5 x 98 Fiat / Alfa /

5 x 100 Renault / Vauxhall / Opel / VW

5 x 108 Ford / Jaguar S /

5 x 110 Vauxhall / Seat / VW / Renault Opel

5 x 112 Mercedes / VW / Audi

5 x 114.3 Mostly Jap / Nissan / Toyota

5 x 120 BMW / VW

5 x 127

5 x 130 Porsche / Original VW Beetle

5 x 139.7 5 x 150 6 x 139.7

*please note these are just as a guide, manufactures change PCD's all the time, always check before you buy*

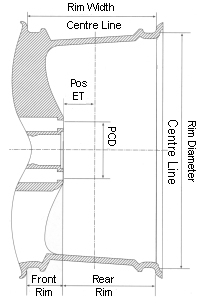

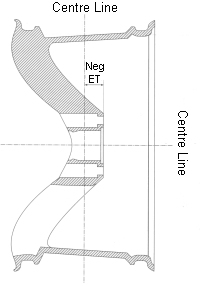

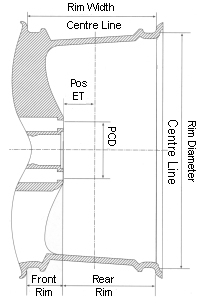

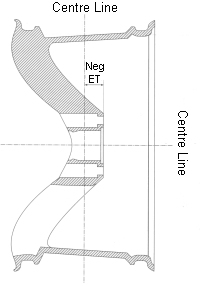

OFFSET (ET) EXPLAINED

Offset is the measurement in millimeters from the wheel centre line to the wheel mounting face. More often than not, offsets are positive(+) where wheel styles tend to be flush or convex. Negative (-) offsets tend to have concave styling.

WARNING: Incorrect offset can seriously affect vehicle performance.

Rim Measurements / Positive Offset / Negative Offset

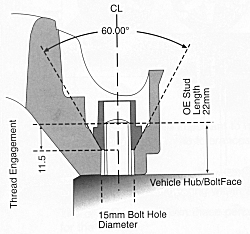

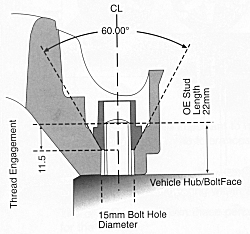

THREAD ENGAGEMENT RULES

For European nut and bolt engagement approvals, 6 turns thread engagement is required for M12x1.5/M14x1.5 and 9 turns for M12x1.25

Example shown opposite:

Stud length = 22mm

Nut = M12x1.5

Bolt Hole Depth = 10.5mm (22 minus 11.5)

Thread Engagement = 7.6 turns (10.5/1.5)

M12 = 12mm Bolt width / 1.5 = mm between peaks of the thread / 60deg tapper = the sides of bolt head are beveled at 60 degrees not flat.

APPLICATION GUIDELINES

The following points must be adhered to BEFORE fitting any wheel and tyre:

Check with the wheel manufacturer that the intended wheel style has sufficient caliper clearances, the correct offset/PCD and accessories have been supplied for the intended vehicle. Wheel manufacturers will rarely credit if tyres are fitted.

Read the maintenance and care procedure supplied by the wheel manufacturer to ensure the maximum life of the rims can be obtained.

Check the vehicle hubs for hub protrusion before mounting the tyres on the wheels, e.g. location pins, temporary fixing screws and hub balance weights. In the event of this, check with wheel manufacturers for the correct wheel application.

Once the tyres have been fitted, check for air leakage between the tyre and rim flange and check the air valves. Quite often valves are supplied for the rims. These valves must be used in the fitting procedure.

Apply the correct tyre pressure stated in the vehicle handbook or recommended by the tyre manufacturer. Incorrect tyre pressure will result in poor tyre wear.

Ensure that the correct torque setting is applied. This procedure must be repeated within 50 miles (80 km). Over-tightening of the nuts/bolts can deform the wheel stud holes. Lack of torque will result in the wheel separating from the vehicle hub.

Note: There are several types of wheel securing nut/bolt seatings. 60-degree cone seating being the most common (radius seatings are applied by German vehicle manufacturers and flat seatings are often applied by Japanese manufacturers). A greater percentage of aftermarket wheel applications use the 60-degree type of seating. Note: mixing of seating is highly dangerous.

Note: It is against the law to drive a vehicle with a wheel and tyre combination the protrudes outside outside the vehicle body.

(NB. this relates to the thread of the tire. with POKING rims, the wheels stick out but the useage of STRECH TIRES alows the tread of the tire to fall within the wheel arch of the car. this can also be adjusted with camber, take advice if poke is what you are looking for).

TYRE UPSTEPS

When upstepping it is important to retain the rolling diameter as specified by the manufacturer. The tolerances for the rolling diameter are governed by ETRTO.

When increasing the wheel diameter, it is necessary to alter the aspect ratio to match the overall gearing within the tolerance of ETRTO.

TYRE PART NUMBER EXPLAINED

Number Examples: Explanation

1) Tyre width in millimeters

2) Tyre aspect ratio (percentage of tyre width)

3) R = Radial construction

4) Tyre diameter (also known as applicable rim diameter)

5) Load index

6) Speed symbol

7) Tyre outer diameter in inches

8 ) Tyre rating (tyre structure-ply rating)

9) Tyre internal diameter in millimeters (millimetric tyres only)

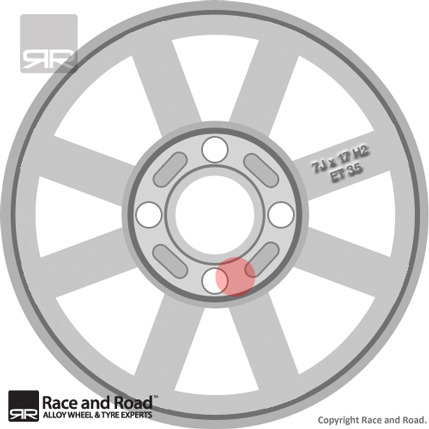

The Average Alloy from behind.

I hope that this guide has been informative. When it comes to wheels "If you dont Know Ask". I specialise in alloys so pm me or pop into the shop. Every car is diffrent so check before you buy, and rember once tires have been fitted YOU CAN NOT SEND THEM BACK!!!!

Thanks for Reading

Happy Modding

The Bishop

WHEEL MEASUREMENTS

A standard measurement for a wheel is given using several figures, e.g. 18 x 8, 4 x 108, 35

This can be broken down as follows:18 x 8 represents a wheel which is 8 inches wide and 18 inches in diameter.

4 x 108 represents the number of studs/bolts and the PCD in millimeters (explained later).

35 represents the Offset (sometimes referred to as the ET).

PITCH CIRCLE DIAMETER (PCD)

The number of bolts used to install a wheel varies from 3 to 8 studs depending on the vehicle make and model. The pitch is the diameter (mm) of the circle that intersects the stud centres. To fix a wheel correctly, the number of studs and the pitch should be the same on the vehicle and the wheel.

The following calculations can be used to work out the PCD:

6-stud - Length 'X' x 2

5-stud - Length 'X' x 1.7012

3-stud - Length 'X' x 1.154

4-stud - Measure the length between the centers of opposite Studs.

In the Trade we use a Measuing Tool for this.

This Tool is calibrated with the Formula's above, so that you simply measure stud to stud, This one will also give American Spec Sizes.

Common Stud Patterns:

3 x 98

4 x 95.25 Mini / MGF

4 x 98 Fiat

4 x 100 Reanult / Vauxhall / Opel / VW

4 x 108 Ford / Peugeot / Citroen

4 x 114.3 Mostly Jap Suzuki / Honda

5 x 98 Fiat / Alfa /

5 x 100 Renault / Vauxhall / Opel / VW

5 x 108 Ford / Jaguar S /

5 x 110 Vauxhall / Seat / VW / Renault Opel

5 x 112 Mercedes / VW / Audi

5 x 114.3 Mostly Jap / Nissan / Toyota

5 x 120 BMW / VW

5 x 127

5 x 130 Porsche / Original VW Beetle

5 x 139.7 5 x 150 6 x 139.7

*please note these are just as a guide, manufactures change PCD's all the time, always check before you buy*

OFFSET (ET) EXPLAINED

Offset is the measurement in millimeters from the wheel centre line to the wheel mounting face. More often than not, offsets are positive(+) where wheel styles tend to be flush or convex. Negative (-) offsets tend to have concave styling.

WARNING: Incorrect offset can seriously affect vehicle performance.

Rim Measurements / Positive Offset / Negative Offset

THREAD ENGAGEMENT RULES

For European nut and bolt engagement approvals, 6 turns thread engagement is required for M12x1.5/M14x1.5 and 9 turns for M12x1.25

Example shown opposite:

Stud length = 22mm

Nut = M12x1.5

Bolt Hole Depth = 10.5mm (22 minus 11.5)

Thread Engagement = 7.6 turns (10.5/1.5)

M12 = 12mm Bolt width / 1.5 = mm between peaks of the thread / 60deg tapper = the sides of bolt head are beveled at 60 degrees not flat.

APPLICATION GUIDELINES

The following points must be adhered to BEFORE fitting any wheel and tyre:

Check with the wheel manufacturer that the intended wheel style has sufficient caliper clearances, the correct offset/PCD and accessories have been supplied for the intended vehicle. Wheel manufacturers will rarely credit if tyres are fitted.

Read the maintenance and care procedure supplied by the wheel manufacturer to ensure the maximum life of the rims can be obtained.

Check the vehicle hubs for hub protrusion before mounting the tyres on the wheels, e.g. location pins, temporary fixing screws and hub balance weights. In the event of this, check with wheel manufacturers for the correct wheel application.

Once the tyres have been fitted, check for air leakage between the tyre and rim flange and check the air valves. Quite often valves are supplied for the rims. These valves must be used in the fitting procedure.

Apply the correct tyre pressure stated in the vehicle handbook or recommended by the tyre manufacturer. Incorrect tyre pressure will result in poor tyre wear.

Ensure that the correct torque setting is applied. This procedure must be repeated within 50 miles (80 km). Over-tightening of the nuts/bolts can deform the wheel stud holes. Lack of torque will result in the wheel separating from the vehicle hub.

Note: There are several types of wheel securing nut/bolt seatings. 60-degree cone seating being the most common (radius seatings are applied by German vehicle manufacturers and flat seatings are often applied by Japanese manufacturers). A greater percentage of aftermarket wheel applications use the 60-degree type of seating. Note: mixing of seating is highly dangerous.

Note: It is against the law to drive a vehicle with a wheel and tyre combination the protrudes outside outside the vehicle body.

(NB. this relates to the thread of the tire. with POKING rims, the wheels stick out but the useage of STRECH TIRES alows the tread of the tire to fall within the wheel arch of the car. this can also be adjusted with camber, take advice if poke is what you are looking for).

TYRE UPSTEPS

When upstepping it is important to retain the rolling diameter as specified by the manufacturer. The tolerances for the rolling diameter are governed by ETRTO.

When increasing the wheel diameter, it is necessary to alter the aspect ratio to match the overall gearing within the tolerance of ETRTO.

TYRE PART NUMBER EXPLAINED

Number Examples: Explanation

1) Tyre width in millimeters

2) Tyre aspect ratio (percentage of tyre width)

3) R = Radial construction

4) Tyre diameter (also known as applicable rim diameter)

5) Load index

6) Speed symbol

7) Tyre outer diameter in inches

8 ) Tyre rating (tyre structure-ply rating)

9) Tyre internal diameter in millimeters (millimetric tyres only)

The Average Alloy from behind.

I hope that this guide has been informative. When it comes to wheels "If you dont Know Ask". I specialise in alloys so pm me or pop into the shop. Every car is diffrent so check before you buy, and rember once tires have been fitted YOU CAN NOT SEND THEM BACK!!!!

Thanks for Reading

Happy Modding

The Bishop

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|